Understanding the American Welding Society (AWS) electrode classification system is crucial for any welder. This system provides a standardized method for identifying and selecting the right electrode for a specific welding application, ensuring weld quality and safety. This guide will delve into the intricacies of the AWS electrode classification, providing a clear and comprehensive understanding of its structure and significance.

Decoding the AWS Electrode Classification System

The AWS system uses a four or five-digit code to classify electrodes. This code provides valuable information about the electrode’s properties, including its tensile strength, welding position, and the type of current required. Understanding this code is like having a cheat sheet for choosing the perfect electrode for the job.

What Does Each Digit Represent?

Each digit in the AWS classification code holds a specific meaning. The first two or three digits indicate the minimum tensile strength of the weld metal in thousands of pounds per square inch (ksi). For instance, an E7018 electrode produces a weld with a minimum tensile strength of 70,000 psi. The next digit represents the welding position the electrode is designed for, such as flat, horizontal, vertical, or overhead. The final digit signifies the type of coating and current to be used. This seemingly simple code provides a wealth of information at a glance.

Common AWS Electrode Classifications and Their Uses

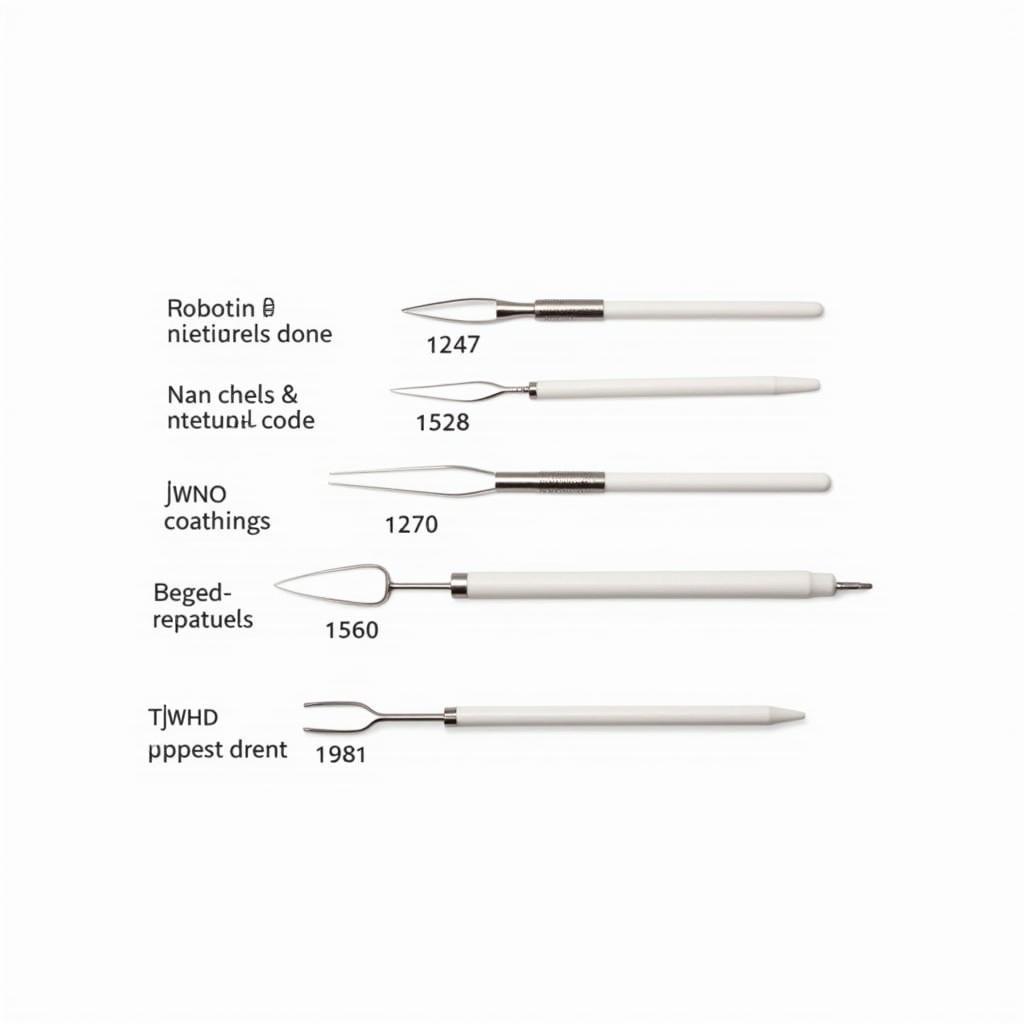

Several AWS electrode classifications are commonly used in various welding applications. E6010 and E6011 are popular choices for general-purpose welding on mild steel, offering good penetration and a stable arc. E7018, known for its high tensile strength and excellent ductility, is often used in structural steel welding. Each electrode type has its unique characteristics, making it suitable for specific applications.  Common AWS Electrodes

Common AWS Electrodes

Why is Understanding AWS Electrode Classification Important?

Using the correct electrode is essential for achieving a strong, reliable, and safe weld. Choosing the wrong electrode can lead to weld defects, compromising the integrity of the structure. The AWS classification system ensures welders select the appropriate electrode for the job, minimizing the risk of failure and maximizing weld quality.

How to Choose the Right Electrode for Your Project

Choosing the right electrode involves considering several factors, including the base metal type, the required weld strength, the welding position, and the available welding equipment. By understanding the AWS classification system, welders can easily identify the electrode that meets the specific requirements of their project. Consulting welding procedure specifications (WPS) also provides valuable guidance in electrode selection.

Advanced Considerations in AWS Electrode Classification

Beyond the basic four or five-digit code, the AWS classification system also includes additional designations for specific properties, such as low-hydrogen electrodes and impact-resistant welds. These additional designations further refine the selection process, ensuring optimal weld performance in demanding applications.

Conclusion: Mastering AWS Electrode Classification

Mastering the AWS electrode classification system is a fundamental skill for any welder. This system provides a standardized language for identifying and selecting the right electrode for every welding application, ensuring weld quality, safety, and efficiency. By understanding this system, welders can confidently tackle any welding project, knowing they have the right tools for the job. Remember, selecting the right electrode, using the AWS system, contributes directly to the integrity and longevity of the welded structure.

FAQ

- What does the “E” in the AWS classification stand for? (A: Electrode)

- What is the significance of the first two digits in the AWS code? (A: Minimum tensile strength in ksi)

- Which electrode is commonly used for structural steel welding? (A: E7018)

- What factors should be considered when choosing an electrode? (A: Base metal, weld strength, welding position, equipment)

- Where can I find more detailed information about AWS electrode classifications? (A: AWS website and publications)

- What are low-hydrogen electrodes, and why are they important? (A: Electrodes with low hydrogen content in their coating, crucial for preventing hydrogen cracking in welds)

- How does the AWS classification system contribute to weld safety? (A: Ensures the correct electrode is used for the application, minimizing the risk of weld failure)

Related Articles:

- Welding Safety Best Practices

- Understanding Welding Processes

- Choosing the Right Welding Equipment

For any assistance, please contact us at Phone: 02043854663, Email: [email protected] or visit our address: Zone 34, Bac Giang, 260000, Vietnam. We have a 24/7 customer support team.